NETWORK

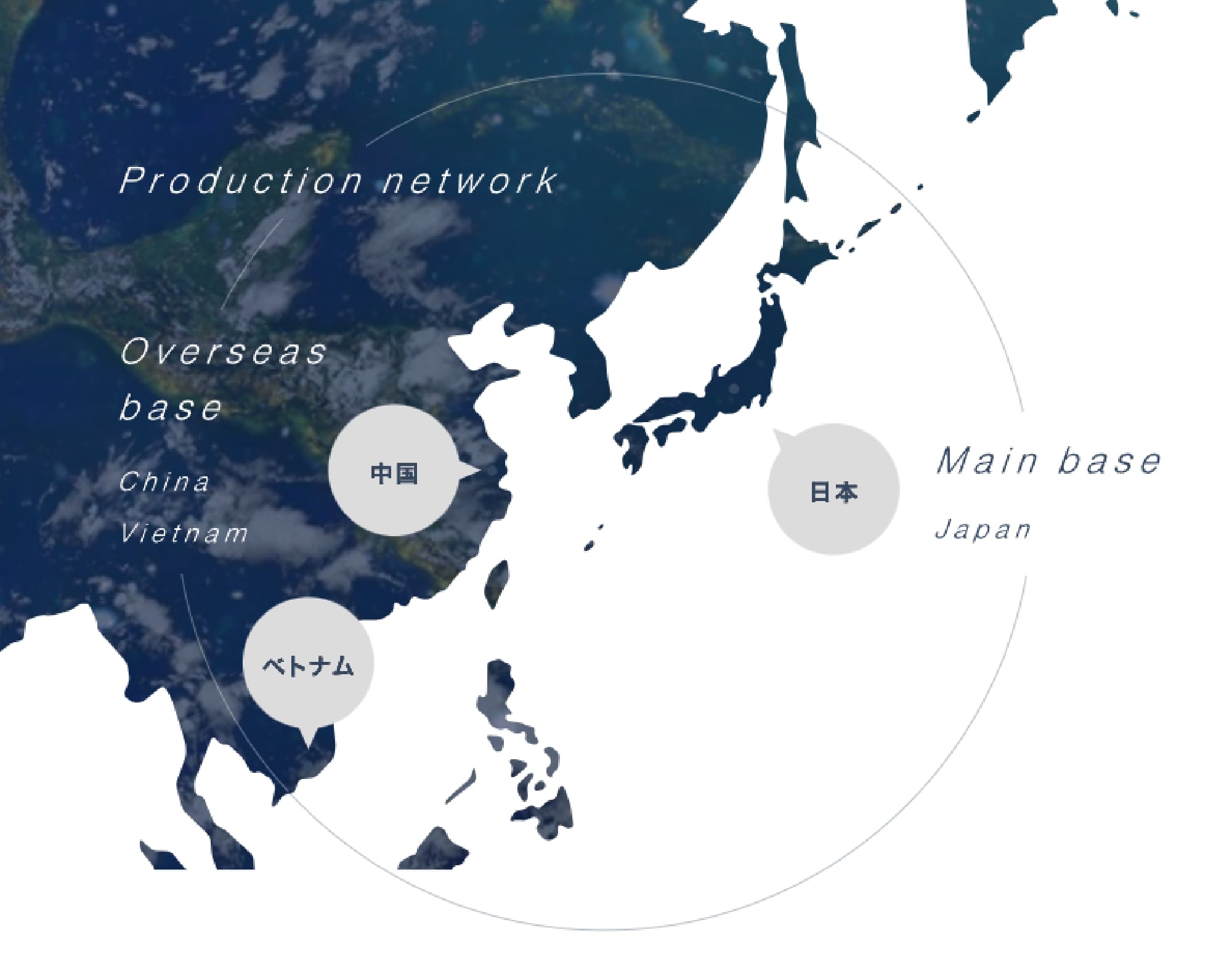

Production network

NETWORK

With production bases in Japan, China, and Vietnam, we integrate with people of diverse values and cultures worldwide. Through innovative ideas and proactive action, we establish Yuwa's technology that breaks conventional norms.

Manufacturing with quality equivalent to domestic factories

We maintain manufacturing quality comparable to our Japanese headquarters while enabling mold production and global mass production.

Both our China and Vietnam factories maintain high cleanliness standards and specialize in precision component production. We have a proven track record supplying primarily micro-precision molded parts, electronic components, camera parts, automotive parts, and medical components.

Equipment capabilities supporting stable production for global customers

We have established a manufacturing system with over 450 injection molding machines and assembly lines combined domestically and internationally.

Furthermore, our overseas factories actively adopt AGV transport and automated assembly, promoting the same level of automation and unmanned operation as our main factory.

YUKA PRECISION

-

Technical Information

We perform small precision plastic molding, mold manufacturing, press processing, and product assembly. Operations are conducted by a workforce of 260 employees, centered around young talent with an average age of 22.5. (As of October 2024)

-

Quality Information

The factory maintains the same high cleanliness standards as Yuwa Japan and produces precision components.

Product information

Micro precision molded parts, relay components, connector parts (smartphones, tablet devices), camera components, automotive parts, medical components, etc.

YUWA VIETNAM

-

Technical Information

With a workforce of 740 employees, we perform small precision plastic molding, mold manufacturing, and product assembly. We have implemented dust-free and unmanned systems comparable to those in Japan and China.

-

Quality Information

We have introduced a high-level Class 10,000 cleanroom in our inspection room for testing optical components and similar items.

Furthermore, we have utilized Autoclaved Lightweight Aerated Concrete (ALC) panels for the factory exterior walls—a first in Vietnam—enhancing the overall cleanliness of the facility.

Product information

Micro-precision molded parts, connector parts (smartphones, tablet devices), camera parts, automotive parts, medical parts, etc.

FUJIFILM YUWA

-

Technical Information

In May 2020, Fujifilm Corporation and Yuwa established a joint venture within Yuwa Vietnam Co. Ltd., a subsidiary of Yuwa.

Full-scale operations commenced in November 2020, manufacturing medical products including blood test kits. We also have a track record of manufacturing diagnostic reagents for novel coronavirus antigen test kits. Fujifilm Yuwa has established a stable production system.

Product information

Medical products such as blood test kits

Equipment and product information is available here

For detailed information, please visit EMIDAS via the button below.

CONTACT

Contact us / Request for information

For inquiries, please contact us by phone or email. Please feel free to contact us.

-

0267-25-8001Contact us by telephone

Business hours: 8:10-17:00 weekdays

-

Contact us by emailContact us by email

Technical consultation and estimates

For inquiries regarding recruitment and other matters, please contact us here.