PLASTIC

Resin mold fabrication

ABOUT

Creating micro-precise molds is the Yuwa Group's signature mold technology.

To maintain ±1-micron precision, our factory operates as a ±0.5°C constant-temperature environment. Machines are mounted on vibration-damping floors, ensuring thorough environmental control during processing.

Furthermore, to achieve high precision machining, many of our machines are custom-specified, reflecting our unwavering commitment to excellence.

Our uniquely conceived air conditioning system utilizes machine exhaust heat, contributing to the global environment with minimal energy consumption.

-

01

Monthly production capacity: 50 molds

Resin mold fabricationCapable of launching up to 50 molds per month. We maintain a production system combining speed and flexibility. -

02

1 micron

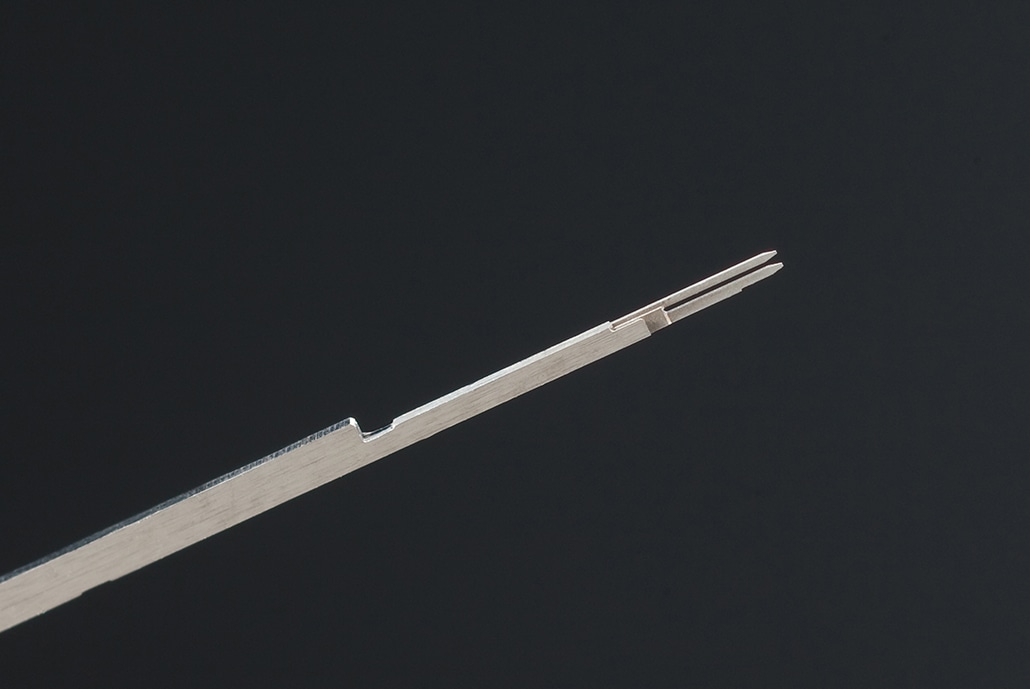

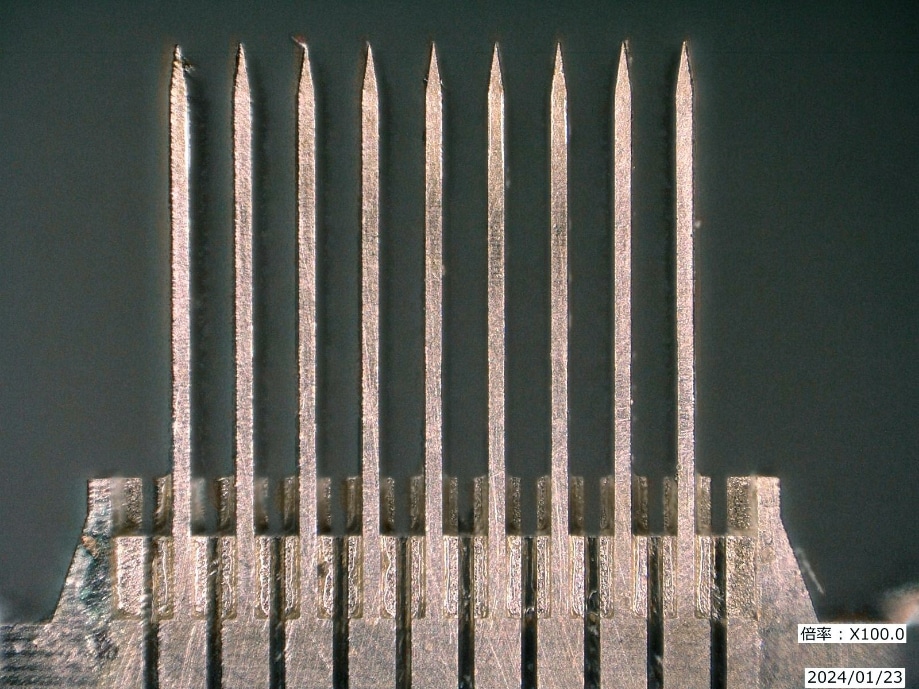

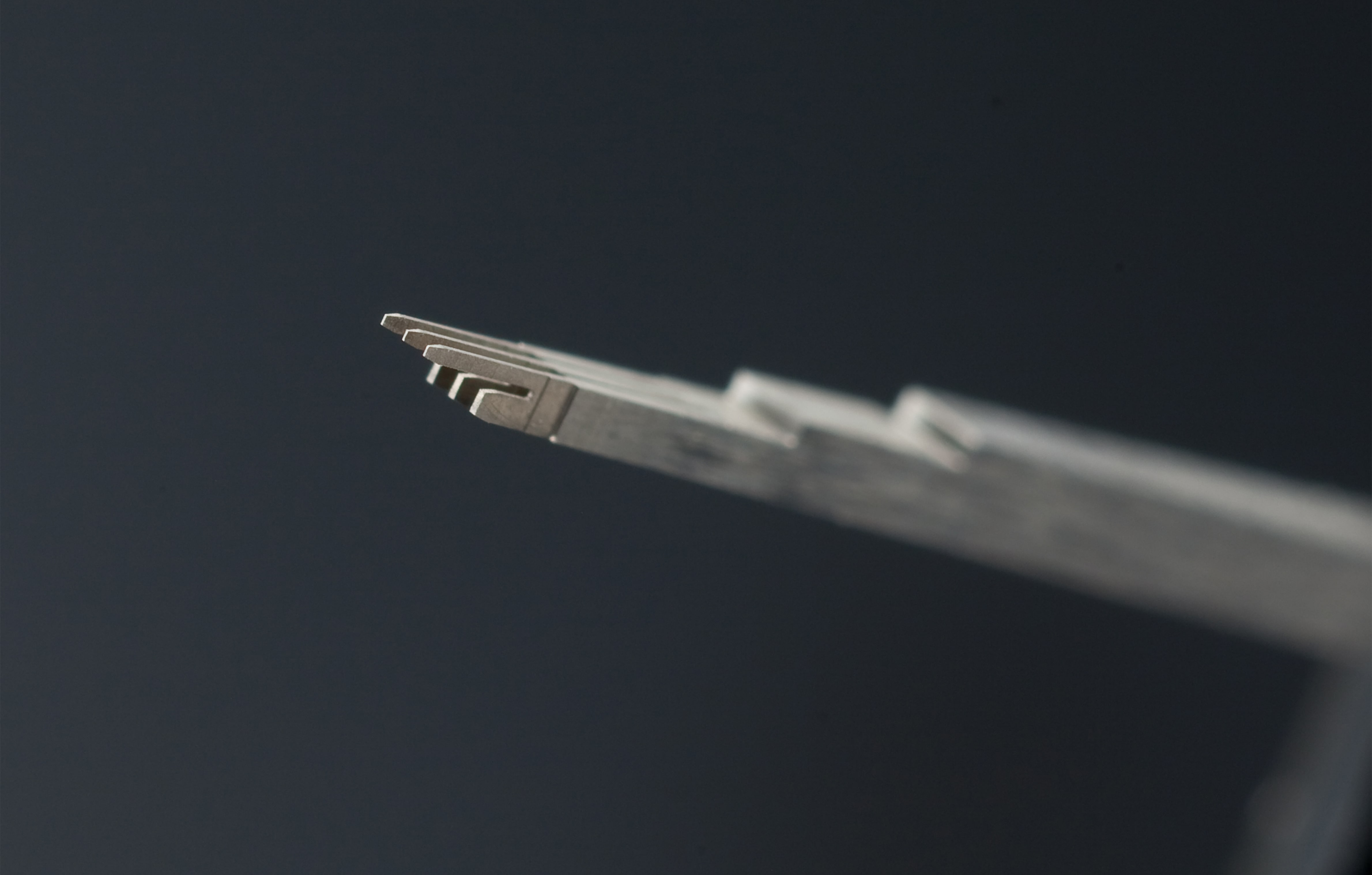

Micro-precision machiningCutting-edge mold manufacturing technology achieving machining precision at the 1-micron level. Supports high-precision molding by accommodating intricate shapes. -

03

World-class Standards

Global productionEstablished a global production system across three bases: Japan, China, and Vietnam. We provide Yuwa's technology to customers worldwide.

The Yuwa Group holds certifications for IATF16949:2016, ISO9001:2015, ISO14001:2015, and ISO13485:2016.

MOLD

PRODUCTION

Introducing the features of Yuwa's mold manufacturing.

Over 7,000 molds manufactured

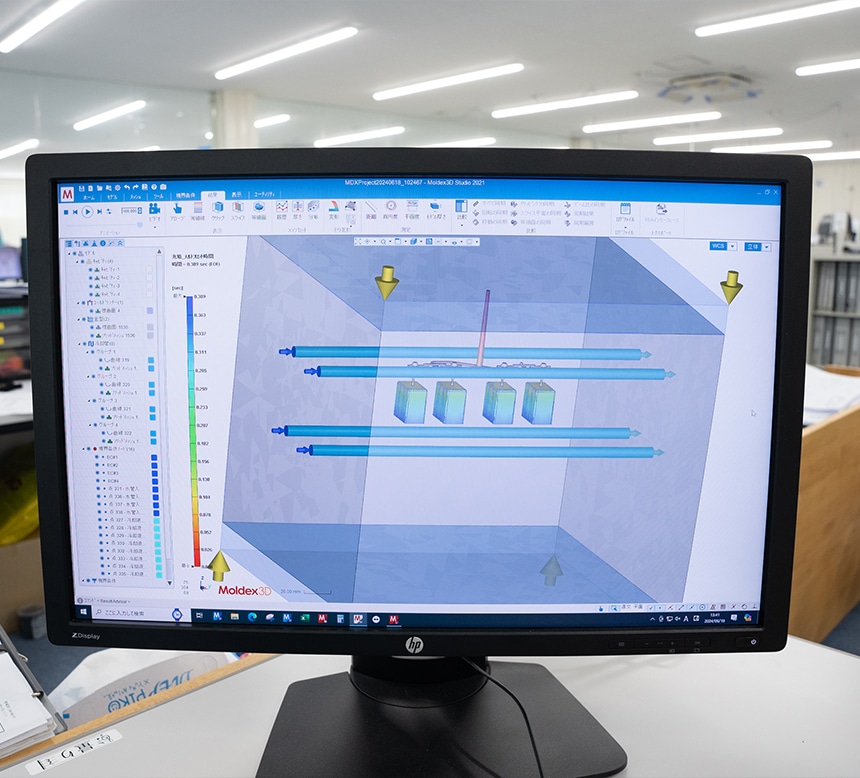

To provide the best proposals tailored to customer requirements, we leverage our experience and track record of over 7,000 molds to design for optimal mass production.

50 Designers Nationwide and Overseas

The company employs approximately 50 mold designers in domestic and overseas factories.

We also review molds manufactured overseas and maintain daily coordination.

±1-micron machining technology and unmanned night/holiday operation

With approximately 200 machining technicians worldwide, we are equipped with state-of-the-art facilities including machining centers, wire EDM machines, spark erosion machines, and grinding machines.

We achieve high precision micro-machining not only by using standard commercial machine tools but also by utilizing Yuwa's proprietary machines, developed in collaboration with machine tool manufacturers.

We pursue and continuously evolve our ±1 micron machining technology. Furthermore, we have established an unmanned operation system during nights and holidays, aiming for 720 hours of automated operation per month.

Assembling over 1,500 parts

We assemble over 1,500 mold components per mold, with some molds requiring more. We aim for completion without adjustments, ensuring the mold is finished simply by assembling components with ±1 micron precision.

Constructing a Constant-Temperature Room with a Unique Air Conditioning System

The Mold Technology Center factory features a constant-temperature room maintained at ±0.5°C.

By eliminating minute expansion and contraction of molded products due to temperature changes and stabilizing the castings themselves, we achieve precision within ±1 micron.

Furthermore, by reusing waste heat from each machine and from air compressors, we contribute to energy conservation. Additionally, we have established an unmanned operation system for nights and holidays, aiming for 720 hours of automatic operation per month.

Processing Fluids Utilizing Rainwater

Processing water used for wire electrical discharge machining. Typically, tap water or groundwater is often used.

While these waters may taste good to drink, they contain minerals and are far from pure water.

Our company stores rainwater, which is closest to pure water, in an underground tank (10,000 L). This water is pumped to the third-floor water softening system, where it passes through a 10μ filter and ion exchange resin to produce softened water.

The ion exchange resin installed in the machine itself lasts five times longer compared to softening tap water, contributing to reduced running costs.

Reuse of Grinding Fluids

The processing fluid for our surface grinding machines is filtered through a filter with a filtration precision of 0.5 microns or less, under temperature control of ±1°C.

Constant agitation within the wastewater recovery tank prevents fluid degradation. This achieves over five years without replacement, minimizing waste.

CONTACT

Contact us / Request for information

For inquiries, please contact us by phone or email. Please feel free to contact us.

-

0267-25-8001Contact us by telephone

Business hours: 8:10-17:00 weekdays

-

Contact us by emailContact us by email

Technical consultation and estimates

For inquiries regarding recruitment and other matters, please contact us here.