PRECISION

Precision injection molding

ABOUT

We specialize in stable production of micro-molded parts using fine precision molds.

Even for products requiring precision, we meet the accelerating demand for ultra-high-precision molded parts by establishing precise design, mold technology, and injection molding techniques.

To mold items weighing less than 0.001 g or with 0.12 mm pitch, our factory maintains a Class 100,000 cleanroom environment.

We pursue thorough automation and labor reduction, maintaining a commitment to 24-hour high-quality production.

-

01

Development Support

Supporting Development to Mass ProductionWe provide technical support from the product design stage to propose the optimal molding method.

We offer consistent support from development prototyping through mass production launch. -

02

450 units

Production System Supporting Global SupplyApproximately 450 molding machines operate across three locations: Japan, China, and Vietnam.

We can flexibly accommodate diverse production lot sizes and product specifications. -

03

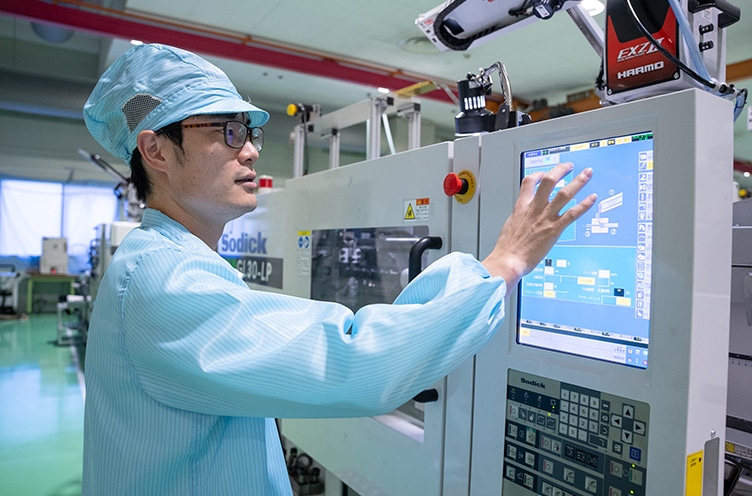

Unmanned and dust-free operation

Automation and a clean environmentWe have automated processes from molding to inspection and established a Class 100,000 (ISO Class 8) clean environment.

We have built an unmanned, dust-free production system that achieves high-precision and stable molding.

PRECISION

Here are the features of Yuwa's injection molding.

Over 450 machines domestically and internationally support mass production.

A total of more than 450 molding machines are in operation in Japan and overseas, of which more than 110 molding machines operate 24 hours a day at the Yuwa headquarters plant.

Some machines achieve monthly production exceeding 5 million units.

Proven track record in molding micro-products for cutting-edge fields

Yuwa manufactures essential micro-connectors, sensors, and plastic/molded parts for FPCs used in next-generation mobility, medical devices, digital devices, and other cutting-edge fields. Leveraging world-class mold technology as our strength, we contribute globally to a wide range of industries.

We can accurately and stably produce micro-products with molding weights under 0.001 g.

Insert Molding

We utilize proprietary technology to streamline hoop insert and part insert processes, delivering automated production combined with image inspection. Furthermore, we have established an integrated production system extending to cut-and-bend operations and tray arrangement.

Molding in a "dust-free" Class 100,000 clean environment

Medical and electronic components are highly sensitive to dust and foreign particles.

Air entering the factory is filtered and maintained at positive pressure to prevent the intrusion of external dust and insects.

Automated Material Supply System

Molding materials are a source of dust.

Equipment is in place to transport materials via hoses from an upper-level material supply room to each machine, avoiding their introduction into the factory floor.

Materials for 80 molding machines are set up by one person during the day and operated unmanned at night.

Integrated Production System from Molding to Image Inspection

Molded products are inspected by image inspection, and good products are packed in shipping bags.

Automating inspection achieves the fastest possible lead times.

CONTACT

Contact us / Request for information

For inquiries, please contact us by phone or email. Please feel free to contact us.

-

0267-25-8001Contact us by telephone

Business hours: 8:10-17:00 weekdays

-

Contact us by emailContact us by email

Technical consultation and estimates

For inquiries regarding recruitment and other matters, please contact us here.