YUWA technology

Yuwa's Manufacturing

ABOUT

Leveraging microfabrication technology, Yuwa specializes in precision resin mold manufacturing and precision injection molding.

The micro-precision molded parts produced by Yuwa are used in smartphones, tablet devices, medical equipment, automotive parts, and more, supporting cutting-edge manufacturing.

FEATURE

We handle everything from mold making to molding, providing one-stop solutions for challenges from prototyping to mass production.

From the development stage, we propose prototypes designed with mass production in mind. This approach shortens development lead times, ensures quality built-in based on ISO 13485, and guarantees safe product supply to meet customer needs.

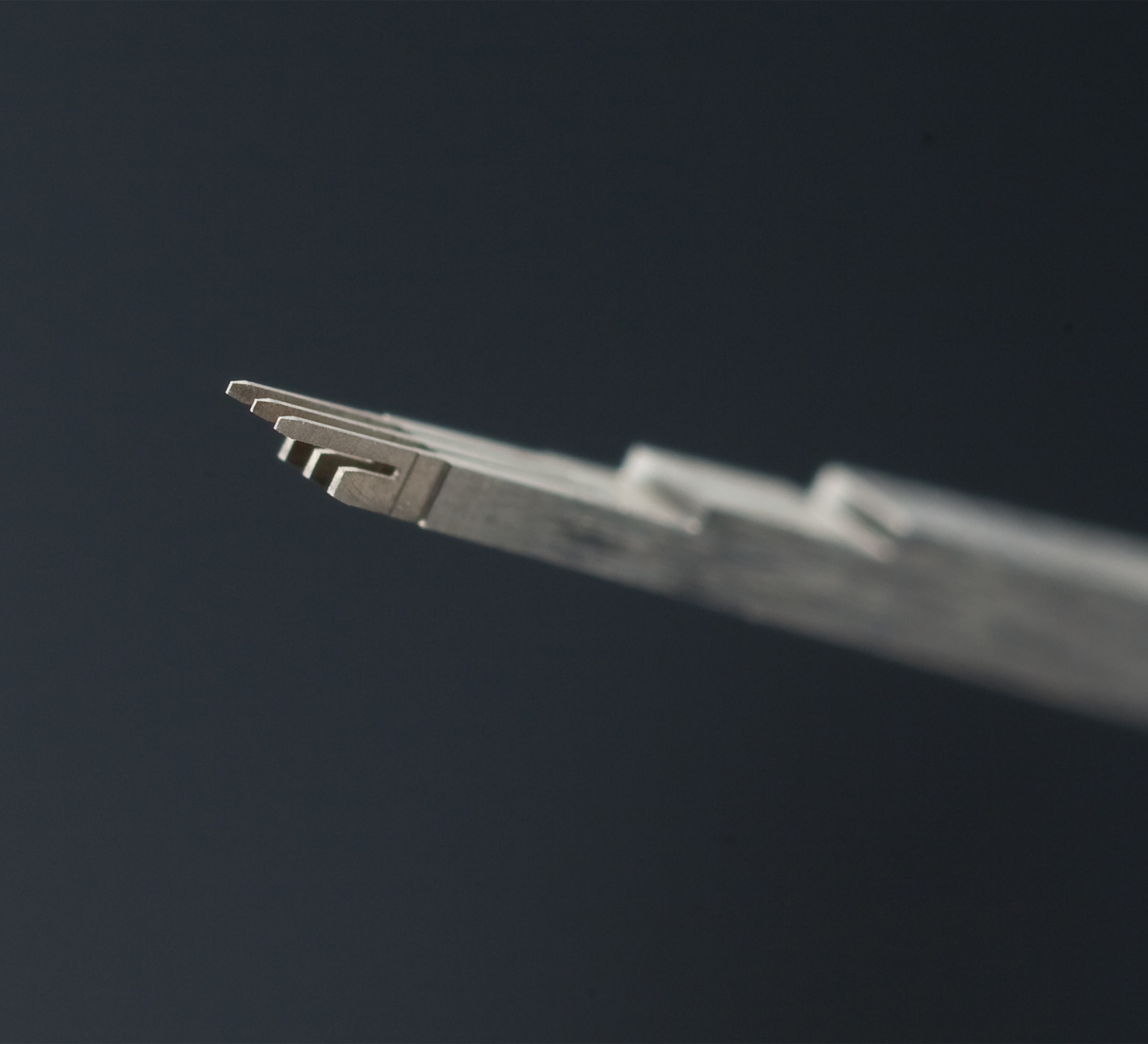

Resin mold fabrication

From prototyping to mass production, precision mold manufacturing with 1-micron accuracy

We handle the production of fine, high-precision resin molding molds through an integrated in-house production system. With high-precision machining to ±1 micron, we provide one-stop service from prototype molds to mass-production molds, ensuring stable quality for mass production.

Precision injection molding

Produce high-precision products with stable quality

We have automated material supply equipment and a 24-hour operation system in place to achieve automated and unmanned operation. Additionally, our molding factory maintains a Class 100,000 cleanliness level to ensure stable, high-quality molding.

Product Assembly

Handling everything from sub-assemblies to final assemblies

We also handle assembly of unit products.

Our expansive factory space and flexible line configuration enable us to cover a wide range, from high-mix low-volume production to mass production.

Please contact us for details.

Initiatives for Acquiring National Skill Certification

At Yuwa, we position the enhancement of each employee's technical skills as a key management priority, actively encouraging and supporting the acquisition of National Skill Certification.

We have established a comprehensive support system aimed not merely at obtaining qualifications, but at genuine technical skill improvement, providing full backing for employee growth.

List of Qualified Personnel

Molding Division

| Name of Qualification | Level | Number of Personnel |

|---|---|---|

| Plastic molding (injection molding operations) | Special | 1 |

| Plastic molding (injection molding operations) | 1 | 6 |

| Plastic molding (injection molding operations) | 2 | 10 |

| Plastic molding (injection molding operations) | 3 | 22 |

Total number of applicants 50

Mold Division

| Name of Qualification | Level | Number of Personnel |

|---|---|---|

| Non-Contact Removal Processing (Special Level Non-Contact Removal Processing) | Special | 2 |

| Machining (Special Level Machining) | Special | 2 |

| Electrical Discharge Machining (Special Level Electrical Discharge Machining) | Special | 1 |

| Metal Heat Treatment (Special Level Metal Heat Treatment) | Special | 1 |

| Non-Contact Removal Processing (Numerically Controlled Sinking Electrical Discharge Machining Operations) | 1 | 1 |

| Machine Processing (Surface Grinding Machine Operation) | 1 | 4 |

| Machine Processing (Numerically Controlled Milling Machine Operation) | 1 | 1 |

| Electrical Discharge Machining (Wire Electrical Discharge Machining Operation) | 1 | 3 |

| Metal Heat Treatment (General Heat Treatment Operation) | 1 | 2 |

| Metal Material Testing (Microstructure Testing Operation) | 1 | 1 |

| Non-Contact Removal Processing (Numerically Controlled Sinking Electrical Discharge Machining Operations) | 2 | 3 |

| Machine Processing (Surface Grinding Machine Operation) | 2 | 5 |

| Electrical Discharge Machining (Numerically Controlled Sinking EDM Operation) | 2 | 3 |

| Metal Heat Treatment (General Heat Treatment Operation) | 2 | 4 |

| Machine Processing (Surface Grinding Machine Operation) | 3 | 8 |

| Metal Heat Treatment (General Heat Treatment Operation) | 3 | 7 |

| Finishing (Machine Assembly Finishing Operations) | 3 | 3 |

Total number of applicants 58

NETWORK

Thorough Quality Control System: Automated Inspection × Constant Temperature Management × Clean Environment

The mold factory utilizes a constant temperature room employing a groundwater circulation system to maintain stable room temperatures. The molding factory performs molding operations in a Class 100,000 environment using equipment equipped with automated image inspection systems. Certified to ISO9001, ISO14001, and ISO13485, we contribute to shortening customer delivery times and high-quality manufacturing.

Bringing Japanese quality to the world

Yuwa Group's Global Production System

We have production facilities in Japan, China, and Vietnam. We manufacture products with quality equivalent to Japan's. As the Yuwa Group, we meet the needs and expectations of customers worldwide.

CONTACT

Contact us / Request for information

For inquiries, please contact us by phone or email. Please feel free to contact us.

-

0267-25-8001Contact us by telephone

Business hours: 8:10-17:00 weekdays

-

Contact us by emailContact us by email

Technical consultation and estimates

For inquiries regarding recruitment and other matters, please contact us here.